Dimensional Inspection Service in Türkiye

LET’S WORK TOGETHER!

Dimensional Inspection-Measurement Service

Our Dimensional Inspection-Measurement Service is dedicated to providing precise and reliable measurement solutions that are critical for maintaining quality standards in manufacturing and production processes. We understand that dimensional accuracy is vital for the functionality, performance, and compliance of your products. Here’s how we can help:

Types of Measurement Inspections

- Metric Threads Measurement: Precise measurement of internal and external threads to ensure they meet specified pitch, diameter, and angle tolerances as per engineering drawings.

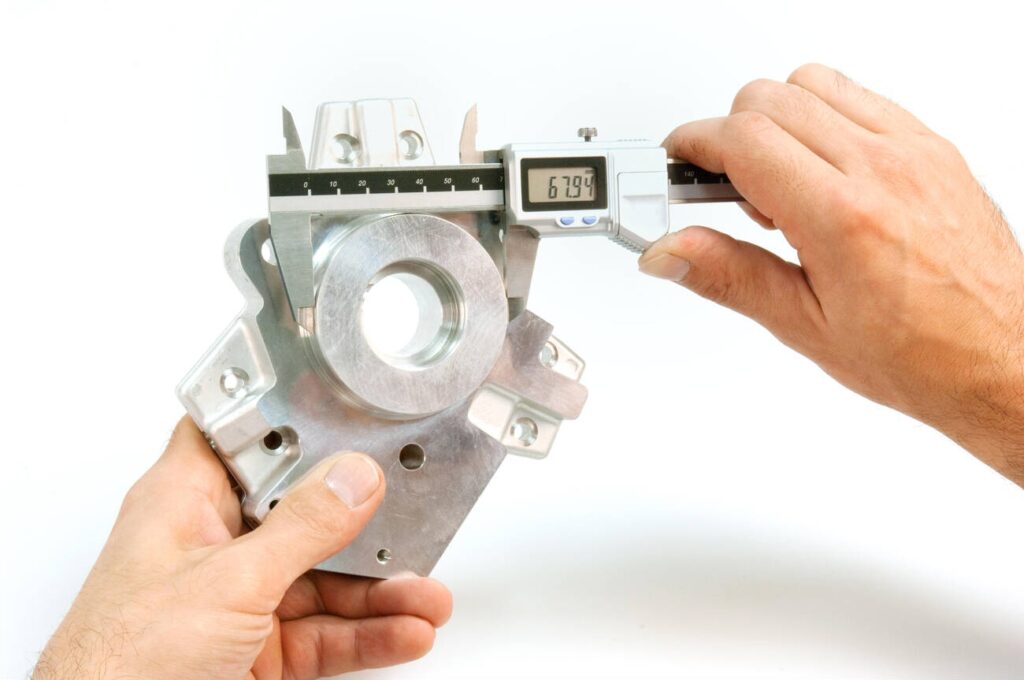

- Internal Diameters: Accurate measurement of the internal diameters of components using tools such as bore gauges and micrometers to ensure compliance with specified dimensions.

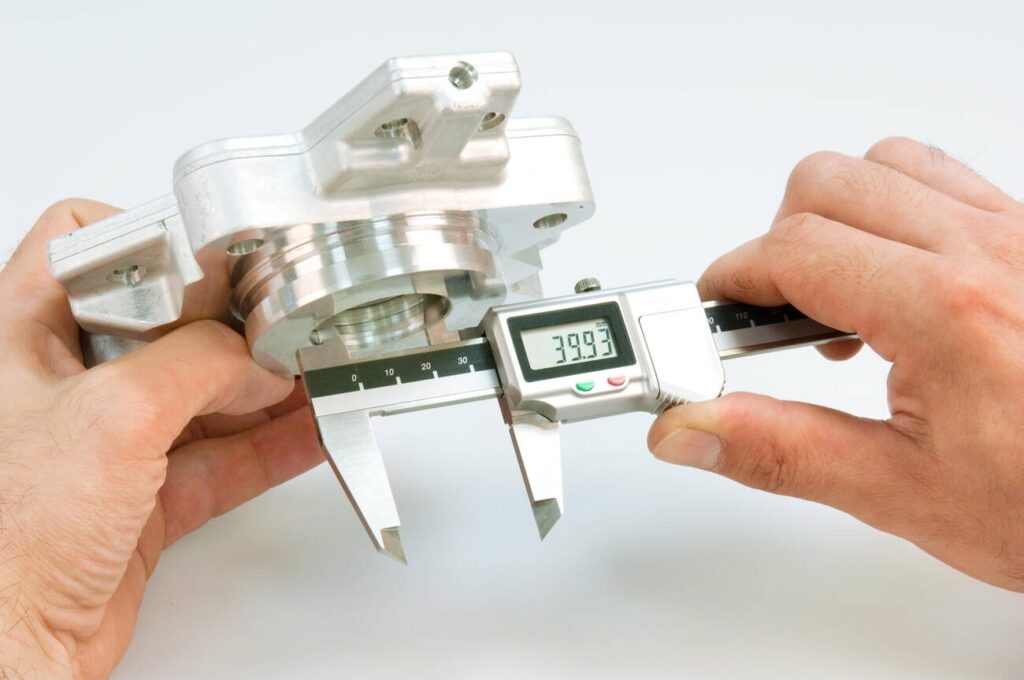

- External Diameters: Measurement of external diameters using calipers, micrometers, and other precision tools to verify adherence to specified tolerances.

- Surface Roughness: Evaluation of surface finish using profilometers and other surface roughness testers to ensure surfaces meet required roughness parameters.

- Geometric Dimensioning and Tolerancing (GD&T): Comprehensive measurement of geometric features such as flatness, roundness, cylindricity, and perpendicularity to ensure they meet specified GD&T requirements.

- Feature Location and Orientation: Verification of the location and orientation of holes, slots, and other features relative to specified datum points.

- Thickness Measurement: Accurate measurement of material thickness using micrometers, ultrasonic thickness gauges, and other appropriate tools to ensure consistency with design specifications.

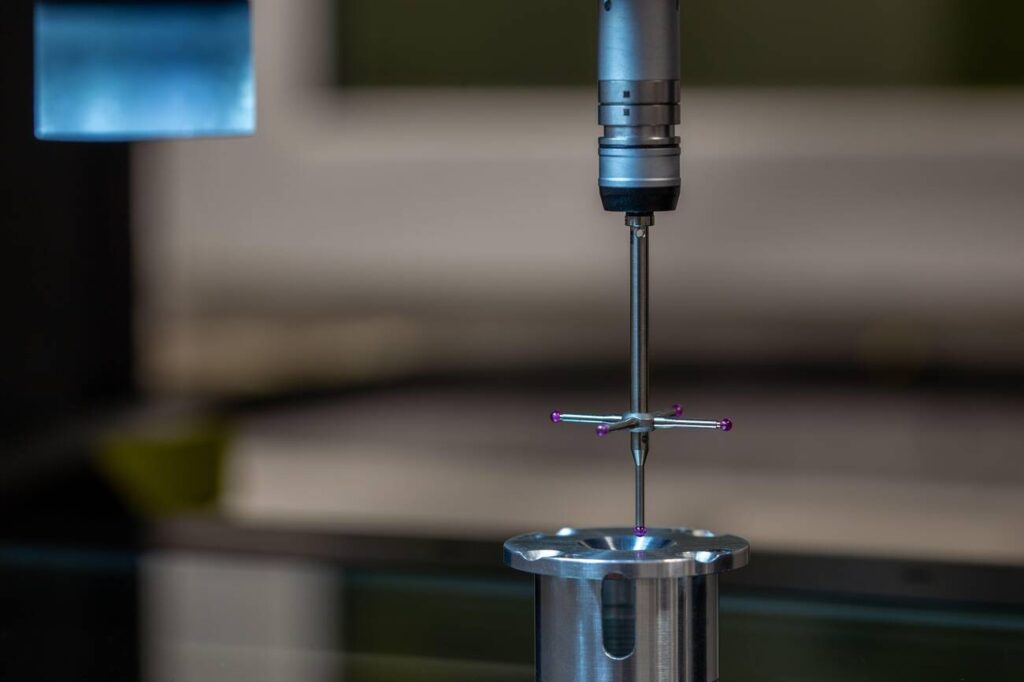

- Angle Measurement: Precise measurement of angles between surfaces or features using angle gauges and coordinate measuring machines (CMM) to verify they meet specified tolerances.

Critical and Important Dimensional Measurements

At QCmatic, we recognize the importance of critical and important dimensional measurements specified by our customers. These measurements are essential to ensure that products meet precise engineering requirements and function as intended. We work closely with our clients to:

- Identify Critical Dimensions: Determine the most crucial dimensions that impact the performance, fit, and function of the product.

- Prioritize Important Measurements: Focus on key measurements that are vital for quality and compliance, based on customer specifications and engineering drawings.

- Customized Inspection Plans: Develop tailored inspection plans that address the critical and important dimensions, ensuring thorough and precise measurement.

- Comprehensive Reporting: Provide detailed reports highlighting the results of critical and important measurements, with clear documentation and analysis to support quality assurance.

Our Services

- High-Precision Equipment: We utilize state-of-the-art measurement tools and equipment to deliver accurate and consistent results. Our advanced technology ensures that even the most complex geometries are measured with precision.

- Expert Technicians: Our team of experienced technicians is skilled in handling various measurement tasks across multiple industries, ensuring that your products meet stringent dimensional specifications.

- Custom Solutions: We offer tailored inspection services to meet your specific requirements. Whether you need one-time inspections or ongoing measurement support, we can design a solution that fits your needs.

- Detailed Reporting: We provide comprehensive reports that offer clear and actionable insights into the dimensional accuracy of your products. Our reports include detailed data and analysis to help you make informed decisions.

- On-site and Off-site Services: We offer flexible inspection services conducted either at your supplier location or in our fully equipped laboratories, ensuring convenience and efficiency.

- Compliance and Standards: We ensure that your products comply with both national and international standards, helping you meet regulatory requirements and market demands.

Why Choose QCmatic?

- Reliability: Our dependable inspection services ensure that you can trust the results and maintain the highest quality standards.

- Precision: We deliver high-accuracy measurements that are essential for product quality and performance.

- Flexibility: Our customizable services allow us to adapt to your specific needs and industry standards.

- Expertise: Our team comprises professionals with extensive industry experience, ensuring expert handling of all your measurement needs.

Industries We Serve

We cater to a diverse range of industries, including:

- Automotive

- Aerospace

- Machinery

- Medical Equipment

- Petrochemicals

- Construction

- Energy