Product Audit Service in Türkiye

Ensure Comprehensive Quality with QCmatic

Product Audit Service

At QCmatic, our Product Audit Service is dedicated to providing thorough and reliable assessments of your products to ensure they meet the highest standards of quality and compliance. Our expert auditors utilize their extensive experience and advanced techniques to evaluate every aspect of your products, ensuring they meet all specified requirements. Here’s how we can help:

Types of Product Audits

- Full Product Audit: Comprehensive evaluation of all product characteristics, including functionality, aesthetics, dimensions, and performance against specified criteria.

- First Article Inspection (FAI): Detailed examination and testing of the first item produced from a new or modified production process to ensure it meets all specified requirements before mass production begins.

- Pre-shipment Inspection: Thorough inspection of finished products before they are shipped to ensure they meet all specifications and quality standards.

- In-process Inspection: Continuous monitoring and auditing of products during the manufacturing process to ensure they remain within specified tolerances and quality parameters.

- End-of-line Inspection: Final inspection of products at the end of the production line to verify that they meet all specified criteria before packaging and shipment.

- Supplier Quality Audit: Evaluation of supplier processes and products to ensure they meet your quality standards and specifications.

Audit Methods

- Visual Inspection: Thorough visual examination of products to identify any surface defects, assembly issues, or cosmetic imperfections.

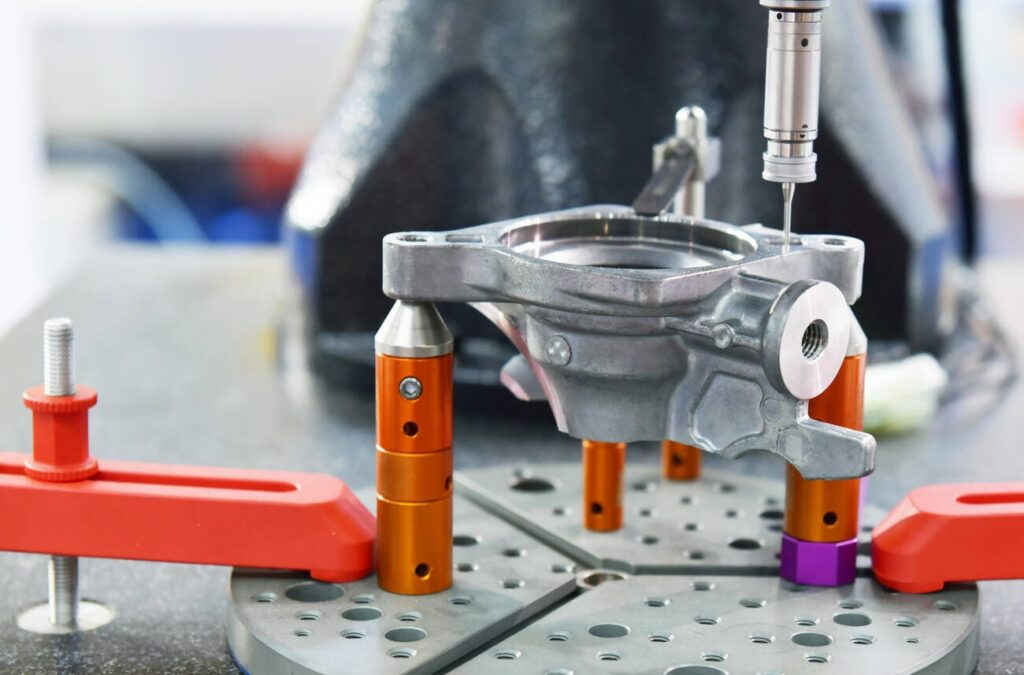

- Dimensional Measurement: Use of precision measurement tools such as calipers, micrometers, and coordinate measuring machines (CMM) to verify product dimensions against specifications.

- Functional Testing: Performing operational tests to ensure products function correctly under specified conditions, including load testing, cycle testing, and environmental testing.

- Non-destructive Testing (NDT): Techniques such as ultrasonic testing, radiographic inspection, and magnetic particle testing to evaluate the integrity of materials and components without causing damage.

- Sample Testing: Selecting representative samples for detailed testing and analysis to draw conclusions about the overall quality of the production batch.

- Documentation Review: Checking product documentation, including drawings, specifications, and quality records, to ensure all requirements have been met and properly documented.

- Compliance Verification: Ensuring products meet relevant industry standards and regulatory requirements through thorough examination and testing.

Our Services

- Comprehensive Evaluations: We perform detailed inspections of all product aspects, including dimensions, functionality, aesthetics, and performance.

- Compliance Verification: Ensuring that products meet all relevant industry standards, regulatory requirements, and customer specifications.

- Customized Audit Plans: Developing tailored audit plans that address the specific requirements of your products and industry standards.

- Detailed Reporting: Providing comprehensive audit reports that document findings, including non-conformities and recommendations for corrective actions.

- Corrective Action Support: Assisting with the implementation of corrective actions to address identified issues and prevent recurrence.

- Ongoing Monitoring: Offering follow-up audits and support to ensure continuous compliance and quality improvement.

Our Process

- Initial Assessment: We begin with a thorough understanding of your specific product audit requirements and quality standards.

- Audit Planning: Develop a customized audit plan tailored to your product specifications and industry standards.

- Execution: Our trained auditors perform detailed audits using industry-standard techniques and equipment.

- Reporting: Provide comprehensive audit reports that document findings and include recommendations for corrective actions if needed.

- Follow-Up: Offer follow-up audits and support to ensure that any identified issues have been resolved.

Why Choose QCmatic?

- Expert Auditors: Our team of highly trained and experienced auditors is dedicated to ensuring that your products meet stringent quality and compliance standards.

- Advanced Techniques: We employ the latest audit techniques and tools to provide accurate and reliable assessments.

- Customized Solutions: Our services are tailored to meet the specific needs and standards of your industry and products.

- Detailed Reporting: We provide clear and detailed audit reports that help you understand the quality of your products and take necessary actions.

- Compliance and Standards: We ensure that your products comply with both national and international standards, helping you meet regulatory requirements and market demands.

Industries We Serve

We cater to a diverse range of industries, including:

- Manufacturing

- Automotive

- Aerospace

- Defense

- Machinery

- Medical Equipment

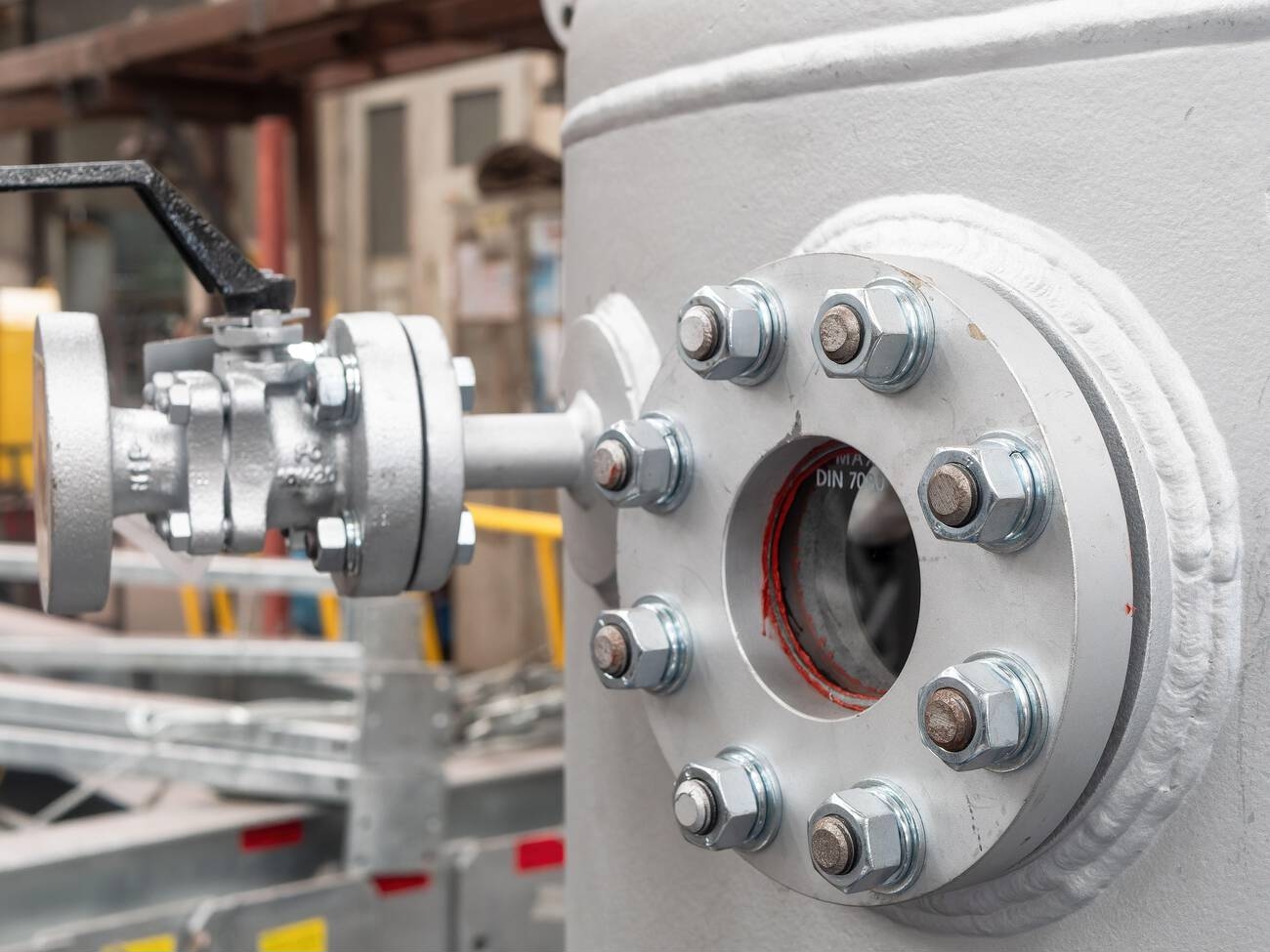

- Petrochemicals

- Construction

- Energy