Medical Equipment Industry

Quality Control, Inspection, and Audit Services for the Medical Equipment Industry

Medical Equipment Industry

Quality Control, Inspection, and Audit Services for the Aerospace Industry

QCmatic provides specialized quality control, inspection, and audit services for the medical equipment industry, helping international customers source high-quality medical devices from Turkish suppliers with confidence.

Applications of Quality Control in Medical Equipment

Dimensional Control

- Purpose: Ensures medical equipment components meet precise design specifications.

- Methods: Utilizing advanced measurement tools like CMM and calipers.

Visual Inspections

- Purpose: Identifies surface defects such as cracks, scratches, and inconsistencies.

- Methods: Conducting detailed visual inspections using magnification tools and trained inspectors.

Process Audits

- Purpose: Verifies compliance with industry standards in manufacturing processes.

- Methods: Reviewing production workflows and operational protocols.

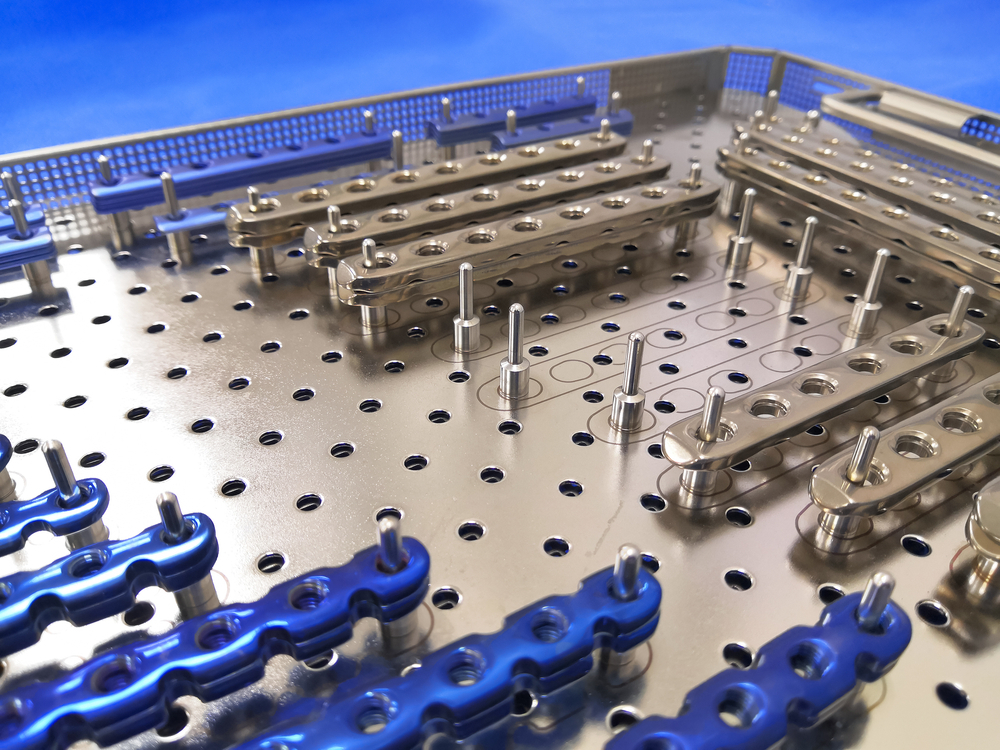

Examples of Quality Control for Medical Equipment

Surgical Instruments

- Example: Inspected surgical instruments for a medical equipment manufacturer, ensuring all dimensions were within tight tolerances using CMM and laser scanning technology.

Diagnostic Devices

- Example: Conducted process audits for a Turkish supplier producing diagnostic devices, identifying areas for improvement and ensuring consistent production quality.

Applications of Inspection in Medical Equipment

Functional Testing

- Purpose: Assesses the performance and reliability of medical equipment components.

- Methods: Conducting load tests, endurance tests, and performance evaluations.

Compliance Audits

- Purpose: Ensures compliance with medical industry standards and regulations.

- Methods: Reviewing documentation and inspecting production lines.

Supplier Quality Assessments

- Purpose: Evaluates suppliers to ensure consistent quality and reliability.

- Methods: Conducting on-site inspections and assessing quality management systems.

Examples of Inspection for Medical Equipment

Imaging Equipment

- Example: Performed functional testing on imaging equipment for a European medical company, ensuring accuracy and performance under various conditions.

Implants

- Example: Conducted compliance audits for a supplier producing medical implants, helping the client achieve certification and improve product quality.

Applications of Audits in Medical Equipment

Process Audits

- Purpose: Ensures manufacturing processes are efficient and compliant with industry standards.

- Methods: Analyzing workflows, equipment calibration, and process documentation

Pre-Shipment Inspections

- Purpose: Ensures medical equipment components meet specifications before shipping.

- Methods: Conducting final inspections and functional tests to verify quality.

Risk Assessments

- Purpose: Identifies and mitigates potential risks in manufacturing processes.

- Methods: Evaluating process controls and implementing corrective actions.

Examples of Audits for Medical Equipment

Prosthetics

- Example: Conducted a process audit for a prosthetics manufacturer in Turkey, optimizing production and reducing defects

Expediting Service

- Example: Performed expediting services for a client needing rapid delivery of medical device parts, ensuring timely completion and shipment.